Silicarbo Emery Fillet

Product Details:

- Product Type Textile Machinery Spares

- Material Steel

- Usage Industrial

300 INR/Piece

X

Silicarbo Emery Fillet Price And Quantity

- 300 INR/Piece

- 1 Piece

Silicarbo Emery Fillet Product Specifications

- Textile Machinery Spares

- Steel

- Industrial

Silicarbo Emery Fillet Trade Information

- 7-10 Days

Product Description

The silicarbo emery fillet consists of a strip or band made of abrasive material, usually silicon carbide embedded in an emery or resin matrix. The abrasive surface of the fillet is carefully shaped and profiled to match the desired contour or shape of the spinning component to be processed.

Frequently Asked Questions :

Q: What is the purpose of using silicarbo emery fillet in textile spinning?

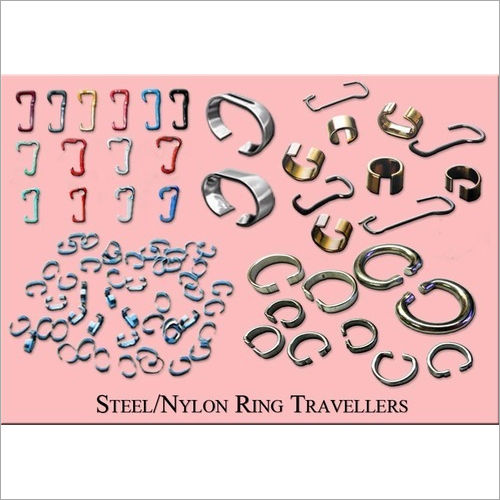

A: Silicarbo emery fillet is used for abrasive operations in textile spinning to enhance the performance and longevity of spinning machine components. It helps remove surface irregularities, polish contact areas, and ensure proper alignment between spinning rings, travelers, and guides, resulting in improved yarn quality and reduced yarn breakages.

Q: How does the silicarbo emery fillet work?

A: The silicarbo emery fillet is mounted on a fillet holder or holder ring and brought into contact with the spinning component during operation. The abrasive surface of the fillet gently wears away any imperfections or buildup on the component, creating a smooth and even surface that promotes better yarn flow and reduces friction.

Q: What are the advantages of using silicarbo emery fillet?

A: Using silicarbo emery fillet offers several advantages. It helps maintain consistent yarn quality, reduces yarn breakages and hairiness, improves the performance and lifespan of spinning components, minimizes maintenance downtime, and enhances overall spinning efficiency.

Q: How often should the silicarbo emery fillet be replaced?

A: The replacement frequency of the silicarbo emery fillet depends on various factors, including the type of spinning process, the quality of spinning components, and the intensity of abrasive operations. Regular inspections should be carried out, and fillets should be replaced when they become worn out or lose their abrasive effectiveness.

Q: Are there different profiles or shapes available for silicarbo emery fillet?

A: Yes, silicarbo emery fillets come in various profiles or shapes to suit different spinning machine components. Common shapes include straight, angled, V-shaped, or custom profiles specific to the requirements of the spinning application. The choice of profile depends on the particular component and the desired outcome of the abrasive operation.

Enter Buying Requirement Details